Green Brewery

Air Date: Week of September 29, 2006

Every worker receives a New Belgium bike after their first year. (Photo: Bryan Simpson)

Businesses have been trying to reduce their energy use for decades. After all, waste is lost profit. But what happens when a business tries to take conservation to an extreme, reusing its own heat and buying all its power from windfarms? Producer Claire Schoen visits a brewery in Colorado to find out.

Transcript

GELLERMAN: It’s Living on Earth. I’m Bruce Gellerman. There’s green beer – the kind you drink on St. Patty’s Day - and then there’s green beer you can make in a green way. That’s what the New Belgium Beer Company is doing. The Colorado-based brewery is using alternative sources of energy, not to save money – it costs them more – but to save the planet. Claire Schoen has our story.

SCHOEN: New Belgium's beers can be found on the shelves in 16 western states today. The company's Hilary Mizia reels off the most popular labels:

MIZIA: New Belgium is a maker of fine Belgian beers. Sunshine Wheat, Blue Paddle, 1554, Abbey and Triple. And then Fat Tire is the one we’re most known for.

SCHOEN: As the 3rd largest craft brewer in the U.S. today, New Belgium is certainly making lots of beer, according to Chief Financial Officer, Christine Perich, and Chief Operations Officer, Jennifer Orgolini

PERICH: Last year we did 370,000 barrels and we're looking at about 415,000 to 430,000 barrels this year.

Finished bottles in the packaging hall. (Photo: Bryan Simpson)

PERICH: That's a lot of bottles. A bottle for every other American. (both laugh)

SCHOEN: It's also making hefty profits.

ORGOLINI: Do you think we say our gross margin?

PERICH: Sure. So our gross margin has run anywhere from 40 to 45%. The revenue you have left over after you’ve made the beer. We’re doing very well.

JORDON: We are profitable. We've always been profitable.

SCHOEN: CEO, Kim Jordon, also explained to me that 100% of the electricity the company uses in its production comes from renewable energy.

JORDON: We see economic benefit to being environmentally sustainable.

SCHOEN: Clearly the company's commitment to using green energy hasn't hurt its profits. But is it, in fact, actually a money maker? I went to Fort Collins, Colorado to find out.

[PARKING LOT]

SCHOEN: In the company parking lot you see more bikes than cars. All employees are given a bike after one year and about a third of them ride to work -- the hardy ones even in cold Colorado winters. Bryan Simpson, Director of Media Relations, pedals into the lot.

Every worker receives a New Belgium bike after their first year. (Photo: Bryan Simpson)

WOMAN: Breezy.

SIMPSON: Breezy?

WOMAN: Well, cause I was going fast.

SIMPSON: Your hair shows it. Whissshhhhh!

SIMPSON: If you look at the bike as metaphor, you know there's no more elegant form of transport that conserves energy and it really can be the future in a lot of ways as well.

[BREW HOUSE SOUNDS]

SCHOEN: It was fascinating to watch beer being made here, on an industrial scale. Big noises. Big machines. Big computers. But still a personal touch, as brew master Mat Gilliland measured out the ingredients by hand.

GILLILAND: So we're brewing a wheat beer today. The wheat in it makes it have a nice light body. And the coriander and orange peel give it a really refreshing punch. These are hops that are vacuum packed in nitrogen to stay as fresh as they can. Best part is you get to smell ‘em. They can be musty or citrus-y or floral. And so I'm weighing them out into the bucket that I'll take upstairs and throw in the kettle.

[POURING INTO BIN]

This is a couple thousand gallons of wert that’s all going to be beer pretty soon. (Pouring hops in.) That boils about 90 minutes.

[KETTLE DOOR SLAMS SHUT]

SCHOEN: It's clear that this process requires plenty of energy. And as "Sustainability Specialist," it's Hilary Mizia's job to keep energy consumption here as low as possible. Around the plant, Hilary is referred to as New Belgium's "Sustainability Goddess."

Sustainability Specialist, Hilary Mizia, in front of a brewing vessel. (Photo: Bryan Simpson)

SCHOEN: As we toured the plant, Hilary pointed out a number of energy-conserving designs they use in their beer-making process. Insulation is a simple one.

MIZIA: We used to have a hot liquor tank that sat on a gas burner. We got rid of that and just do a well-insulated tank. So, that right off the bat saves a lot of energy.

SCHOEN: Then there is the "Wert Chiller," which takes heat produced by the boiling brew and uses it to heat up the next batch.

MIZIA: So as you can tell we have a lot of heat that's created during the process of making beer, but we also need a lot of heat in the process. So if we can recycle that heat as much as possible, then we’re saving on electricity.

SCHOEN: Then Hillary showed off the company's pride and joy: the Merlin Brew Kettle, which is 4 times more efficient than a traditional model.

MIZIA: The brew kettle is where most of the electricity is used. So when you consider you're boiling 6200 gallons, then you're saving quite a bit.

SCHOEN: New Belgium also uses green building concepts to reduce the costs of heating and cooling both the brew house and the offices. Hilary pointed out the sun tubes in the packaging hall. They looked like bright lamps. But....

Suntubes light up the packaging hall with natural sunlight. (Photo: Bryan Simpson)

SCHOEN: Taken together, You'd think these steps would add up to considerable cost savings. But how much? Financial Officer, Christine Perich:

PERICH: We don't necessarily go into every decision that's made that's sustainable and say, "This is the financial impact of the lighting decision that we've made." So it's difficult to sort of extract those pieces and tie some financial metric to it.

SCHOEN: While New Belgium was trying to conserve electricity at every turn, it was still using a lot of it. So in 1998, the company made the decision to switch from coal to wind as its source of electric power. At that time, wind cost more than coal -- by two and a half cents a kilowatt hour. New Belgium is an employee-owned, private company and workers are involved in decision-making.

[LUNCH ROOM SOUNDS]

WORKER: So, four veggies and a couple of meats in there.

WORKER: What are you going with, Mason?

WORKER: Uh, veggie.

SCHOEN: I met with several workers during their lunch break who told me how it happened. They gave me pepperoni pizza and food for thought.

WORKER: The meeting where we looked at voting on wind power was a typical monthly staff meeting. But during that meeting it was determined that wind power is more expensive than regular power. And our bonuses would be smaller because we'd be spending more money on the same electricity.

WORKER: It was like 26% more expensive to do wind power - the number sticks in my mind

WORKER: It was five more cents a barrel, I remember.

WORKER: I remember thinking at the time this is going to be a long contentious meeting.

WORKER: People are going to be like, "Well, that's going to come right out of my pocket. I don’t want to do it.

WORKER: Then everybody kind of looked at each other, as I remember, and you know we had this consensus voting system where you put a thumb up if you’re in favor of something or a thumb down if you’re not.

WORKER: When I looked around the room and there was all those thumbs up it was like, "This is something bigger than what I assumed it was."

SCHOEN: So why did these employees vote to pay extra for wind, when it would come out of their own pockets? Some say they were taking into account the health and environmental costs of coal -- like mercury and soot pollution -- even though those are not reflected on the company's balance sheets.

MIZIA: There are a lot of hidden costs to coal. There is environmental reclamation costs, there is huge health care costs, as well as emission factors. Those have huge price tags that go on for a long time, possibly multi-generations. So financially the payback is actually going to be much better on something like a wind turbine than on a power plant that is fueled by coal.

WORKER: And I think conventional electricity is really rising now, so it could very well be that wind power will be the more economical choice within a couple of years. We're really advocating for the idea that sound environmental practices mirror solid business practices.

SCHOEN: And wind power is turning out to be a good financial bet for New Belgium.

MIZIA: A few years ago the price of wind power dropped drastically. When we first signed on it was two and a half cents more per kilowatt-hour. Now it's down to one cent.

SCHOEN: That's because more and more businesses are buying into the utility company's wind program.

MIZIA: The more that people are using it, the lower the price of wind. So it's exciting. We've been a part of this major growth.

SCHOEN: Then, having opted to pay more for wind power, the incentive to conserve was even stronger. Chief Financial Officer, Christine Perich, and Chief Operations Officer, Jennifer Orgolini:

PERICH: The fact that we were willing to invest in wind power, pushed us to create efficiencies and to do other things.

ORGOLINI: It sort of started us off making green choices for energy investment.

PERICH: I mean it would be hard to do the math on that, but I have to believe that net net we're still ahead of the game. That's my gut, I don't know that mathematically. Do you believe that?

ORGOLINI: Absolutely I believe that.

SCHOEN: Once again, faith-based mathematics. But it all made sense. And I had still not factored in that New Belgium gets some of its fuel -- methane -- from its own wastewater.

[OUTSIDE AT CO-GENERATION FACILITY]

MIZIA: So now we’re walking out to the process water treatment plant.

WEAVER: Hillary took me to meet Brandon Weaver, who operates this "co-generation" facility. First the brewery's waste liquid flows into an anaerobic, or oxygen-free, tank filled with hungry bacteria.

MIZIA: After we’re done brewing beer there’s all kinds of proteins and things left in the water, and so that serves as food for the microbes, the little bugs that live in the anaerobic environment. And so they digest that.

WEAVER: So as the bacteria is cleaning the wastewater they release this bio gas that is very methane rich, it's about 85 to 89% methane.

MIZIA: You could look at it as bug farts. (laughs) That's one way to look at it (laughs).

WEAVER: They're producing this reusable byproduct that we can send back to the brewery, burn in a combined heat and power engine, and produce electrical and thermal energy.

[FOOTSTEPS TO METHANE TANK]

MIZIA: That is our new methane storage tank and it’s actually a balloon. It looks like metal but it's a balloon. I didn’t believe it myself until I touched it.

[OUTSIDE SOUNDS NEAR PONDS]

WEAVER: From there we go into our second stage which is aerobic treatment, bacteria that operates on the exact opposite principle, likes a lot of dissolved oxygen to perform.

MIZIA: The water is being churned around by forced air vents.

WEAVER: And from there we flow on to the city’s treatment plant.

SCHOEN: I peered into the frothy, bubbling basin, hoping to spot the little microbes doing their aerobic exercises.

WEAVER: Hey, there's Mandy, we need you.

SCHOEN: But Brandon led me on, down into a tunnel that ran beside the anaerobic basin. Here, he and Mandy Miller drew water samples from the basin.

[WALKING INTO A TUNNEL]

MILLER: This is the tunnel on the side of the basins. And it's where we take the samples.

WEAVER: So it looks like everything's flowing here.

MILLER: You take that sample and it just goes Buucchhhhh, Pshiich. Sometimes you just get sort of a sludge shower.

WEAVER: We're performing certain analytical tests every step of the way to make sure that the pollutant level of the wastewater is being reduced after each stage of the process.

SCHOEN: Here the numbers were more solid. New Belgium creates 14% of its energy use with methane gas. But it actually saves more than that -- closer to 25% because it uses methane power during "peak" hours when wind power rates are highest.

ORGOLINI: The utility charges a premium for electricity during certain times of the day, and so we've programmed our co-generation plant to run coincidental to those peak times.

JORDON: And so the payback is better, because we're able to take the most expensive time of day and use our own energy source rather than the city's wind power.

SCHOEN: Cleaning the water through this process is also saving the company ten to fifteen thousand dollars a month in CITY surcharges for waste water treatment.

WEAVER: We're reducing the pollutant load in the water about 98.9% before we send it on to the city.

JORDON: So it’s a really very elegant solution to energy production for us.

SCHOEN: When the beer is brewed and bottled, there's still one more way the reduce dependence on fossil fuels -- with bio-diesel delivery trucks.

HINES: So this is one of three trucks that we run Fort Collins in. And uh, yeah we run all our trucks off of bio diesel.

SCHOEN: Shawn Hines is known around town as the "Pharaoh of Flow". He's making the Fort Collins delivery rounds today with Michael Klepper:

[UNLOADING KEGS]

HINES: What do we need?

KLEPPER: Two Fat, three Sun......

HINES: Two Fat, three Sun. You want to take three Skinny in? Alright!

SCHOEN: Inside Lucky Joe's pub, Shawn has to maneuver two kegs down a staircase that's barely the width of his shoulders.

[INSIDE THE PUB]

HINES: Man it is going to be tighter than stripes on a watermelon through here.

Oh Daddy! Stairs! They’re about 170 pounds a piece, and you figure each guy moves I'd say about 40 to 50 a day. So, definitely earn their keep. (chuckle)

[INSIDE BEER CELLAR]

HINES: Ready to motor on?

[TRUCK STARTS]

KLEPPER: It's easy making friends when you're driving around in a big red beer truck.

SCHOEN: On the way to the next stop, I asked Shawn about the price of bio-diesel.

HINES: It’s actually comparable in price to regular diesel.

SCHOEN: I pressed Shawn on this point and so he made a call to check prices.

HINES: (on the phone:) Hey, Kirk, what’s going on man? Hey, ball park, what’s the going rate on bio right now? So it is more, more than regular diesel right now? Yeah, that sounds about right. Let me give you a shout back here shortly. Alright.

HINES: (to me) So it’s more expensive right now by about ten, eleven cents.

SCHOEN: So, if it isn't saving money, why is the company doing it?

HINES: It's a very, very family oriented place. You can't sling a cat around the brew without hitting a newborn on every given week. And we want our kids to have the best future and bio-diesel seemed like a natural step.

SCHOEN: I kept running up against lots of good intentions. But there just wasn't much concrete data.

ORGOLINI: You've probably noticed, we don’t have the hard numbers to make the decisions in a lot of cases. I mean we are profitable overall, and so we know that the decisions that we've made have been the right ones for us, but we don’t take every decision apart financially.

JORDON: But make no mistake about it, we know that profit is an essential component of running this company. We can be as groovy as we want to be, but if we’re not profitable we’re not gonna keep the doors open.

SCHOEN: If the brewery hasn't quantified the value of its energy decisions, it would have an even harder time measuring the value of its green image. But New Belgium goes about marketing just like any other beer vendor. Well, maybe not quite like the others. It's traveling bicycle and beer festival called the "Tour de Fat," in honor of their Fat Tire beer, landed recently in San Francisco's Golden Gate Park.

[FESTIVAL SOUNDS]

WINN: (on stage) Welcome to the 3rd annual Tour de Fat San Francisco edition. Can you all hear me out there in the land of beer and bicycles? I am one of your hosts from the brewery. My name is Captain Ballyhoo.

SCHOEN: Chris Winn is the brewery's "Event Evangelist."

WINN: (on stage) Know that you are part of a clean movement. The cups are not plastic, those are made out of corn. And they can be composted. Our volunteers will not go compostal on you unless you take one of those cups and try to throw it in the trash. (bike bell sounds)

SCHOEN: A non-official survey of local beer drinkers showed the message is getting through.

[BAR SOUNDS]

PATRON: I'll have a Skinny Dip.

PATRON: Go ahead and pour me another Blue Paddle please.

PATRON: And we're playing pool. And drinking New Belgium beer.

PATRON: We've heard good things about the company. They've got their own little water treatment thing.

PATRON: They get most of their power generated from wind.

PATRONS: They make it very evident in all of their marketing.

PATRON: Their commercials show a guy on a bicycle.

PATRON: I feel better about drinking it because they're environmentally friendly.

SCHOEN: But a lot of people I talked to at New Belgium were also defensive about their green advertising - worried that it would be perceived as "green washing".

JORDON: We’re trying to figure out where that elegant line is between letting people know who we are without doing that, "Look at me, look at me, look at me? Aren't we great, aren't we great?” And I feel like we walk that line on little tiptoes.

SCHOEN: Maybe it's just a good beer. Maybe the country is ready for an alcoholic drink that's this green. For now New Belgium is doing very well, by doing good.

PATRON/WAITRESS: Can I get a Blue Paddle and it looks like we need another order of cheesy fries.

SCHOEN: For Living on Earth, I'm Claire Schoen in Fort Collins, Colorado.

[Dan MacKenzie “Cheers to the Beers” from ‘Monster House’ (Amygdala Music – 2003)]

Links

Living on Earth wants to hear from you!

Living on Earth

62 Calef Highway, Suite 212

Lee, NH 03861

Telephone: 617-287-4121

E-mail: comments@loe.org

Newsletter [Click here]

Donate to Living on Earth!

Living on Earth is an independent media program and relies entirely on contributions from listeners and institutions supporting public service. Please donate now to preserve an independent environmental voice.

NewsletterLiving on Earth offers a weekly delivery of the show's rundown to your mailbox. Sign up for our newsletter today!

Sailors For The Sea: Be the change you want to sea.

Sailors For The Sea: Be the change you want to sea.

The Grantham Foundation for the Protection of the Environment: Committed to protecting and improving the health of the global environment.

The Grantham Foundation for the Protection of the Environment: Committed to protecting and improving the health of the global environment.

Contribute to Living on Earth and receive, as our gift to you, an archival print of one of Mark Seth Lender's extraordinary wildlife photographs. Follow the link to see Mark's current collection of photographs.

Contribute to Living on Earth and receive, as our gift to you, an archival print of one of Mark Seth Lender's extraordinary wildlife photographs. Follow the link to see Mark's current collection of photographs.

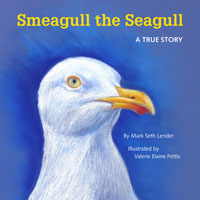

Buy a signed copy of Mark Seth Lender's book Smeagull the Seagull & support Living on Earth

Buy a signed copy of Mark Seth Lender's book Smeagull the Seagull & support Living on Earth