Wearing Local

Air Date: Week of October 15, 2010

Rebecca Burgess has set up a challenge for herself: for one year, she will dress in clothes made in fibers that are grown – and made – within 150 miles from her California home. Burgess created The Fibershed Project to point out that commercially-made clothing has an enormous carbon footprint and to show that fashion can be both attractive and sustainable. Lonny Shavelson reports.

Transcript

GELERMAN: In Northern California there’s a new fashion: think globally-----dress locally. Clothing makes the environmentalist for a woman who has sworn off materials from afar and will only dress in local-ware. Reporter Lonny Shavelson has our story.

[BIKE SOUNDS]

SHAVELSON: On a hot day in hilly suburban Fairfax California, Katherine Jolda is pumping her bicycle pedals. But the bike doesn’t move. That’s because the bike chain has been detached from the wheel, and attached to two large spinning metal drums coated with fine teeth rotating against each other. Jolda feeds raw wool, right off a sheep, into what she calls her carding contraption.

JOLDA: It’s carding the wool, and carding is basically brushing the wool out.

SHAVELSON: The drum’s teeth yank the wool in, chew on it, and then spit it out the other side.

JOLDA: And all the fibers are smooth and it’s untangled. And from there, I make felt from it.

[WOMEN’S VOICES]

SHAVELSON: Jolda is teaching an energized group of women to start with wool from local sheep, and finish with clothing for Rebecca Burgess, a 32-year old lover of textiles and the environment. She’s vowed that every item of clothing she wears in the next year will be made from local materials.

BURGESS: I thought I was quite the environmentally conscious person, but I had a closet packed with clothes. 15 pairs of pants, 30 shirts, 20 sweaters…..

SHAVELSON: Burgess learned from Patagonia’s Footprint Chronicles that the production and shipping of much of the clothing she owned put some 40 times its weight in carbon dioxide into the atmosphere, and that enormous textile factories are huge fresh water polluters. So she cut the size of her wardrobe.

BURGESS: Two skirts, two pairs of pants, one sweatshirt, one sweater, a swimsuit…

SHAVELSON: But for Burgess, that didn’t go far enough to protect the environment. She knew she loved cotton.

BURGESS: And so I thought if I could find a cotton farmer.

SHAVELSON: So she asked around, and…

BURGESS: She’s 90 miles from my front door, growing cotton.

SHAVELSON: She also loved wearing wool clothes from alpaca, a small version of a llama.

BURGESS: And I looked at where’s the alpaca being raised. Well, 147 miles from my front door.

SHAVELSON: And that was the birth of the Fibershed Project. Just like your watershed geographically defines your supply of water, a fibershed is the region that supplies your clothing fibers. Right now, it’s the entire world; not very local. Burgess has limited the source of materials for her clothes to a radius of 150 miles of her house-- a local fibershed. In support, dozens have joined to help make her clothes.

[SOUNDS OF GROUP: And then you’ll take the second half of the wool…]

SHAVELSON: In Burgesses’ backyard garden of plants grown for their dyes, Katherine Jolda, removes the wool from the bicycle carder and wets it with hot water to begin forming felt.

JOLDA: Felting really is the most efficient way that I’ve found of turning the raw material into a useful apparel.

SHAVELSON: Jolda hands the felted wool to Burgess.

[SOUNDS OF STIRRING POT]

SHAVELSON: She immerses it in a huge pot of boiling water richly colored with indigo dye from plants she’s grown…

BURGESS: And I’ve been raising it and honing it through seed selection, to grow well in my climate.

SHAVELSON: Okay, reality check. Burgess lives in the San Francisco Bay Area. So do about seven million other people. How many can have their clothing come from local sheep or cultivate indigo for color? Can this be scaled up to any practical environmental benefit?

ULASEWICZ: No, not domestically. It’s not a scaleable idea.

SHAVELSON: San Francisco State University Apparel professor Connie Ulasewicz co-authored the book ‘Sustainable Design.’ She says the fibershed project is dependent on Burgesse’s extraordinary knowledge and dedication in a geographic area rich in natural plant fibers, animals and activists.

ULASEWICZ: I think this is an ecological curiosity going on in Northern California.

SHAVELSON: But, says the professor, criticizing the Fibershed Project because it can’t be scaled up to millions of clothing buyers in a fabric-based environmental revolution misses the point. This project she says, reflects a general movement in the garment industry toward sustainability.

ULASEWICZ: Sustainable design, green design, eco-design. How can we simplify, reduce carbon footprints. There is a great movement to produce local, to manufacture local.

SHAVELSON: And in that sense, she says, the Fibershed Project should not be judged by whether it’s upwardly scaleable in money or marketing…

ULASEWICZ: But scaleable in the idea of the value and the meaning for this individual and what others can learn from that, it’s interesting, it’s more than interesting. What she is doing with her inspiration for this project is also the idea of I can sustain myself.

SHAVELSON: Burgess admits that a local wardrobe is for the rare few, like her, with time, skills, and a lot of supportive friends to design, dye, weave and sew. But she says the Fibershed Project also illustrates the grand ecological errors of the textile industry. Take the wool being fed into the backyard bicycle-carding mill.

[BICYCLE SOUNDS]

SHAVELSON: The region’s sheep are raised for meat, not wool. The ranchers had been throwing the wool into landfills, 70,000 pounds of it a year— until Burgess started gathering some for her clothes. The rest still goes to landfills. Says Burgess…

BURGESS: We’re importing millions of pounds of wool from New Zealand, it’s being milled in China, and yet we’re throwing wool away here.

SHAVELSON: And since this all started with Burgesse’s realization that her commercially-made clothes create a huge carbon imprint—she’s now calculating the environmental impact of her fibershed clothes. What’s her carbon output when she drives to sheep ranches to get wool? Or transport locally grown cotton just for her use? How much water does it take to wash the wool and cotton, irrigate her dye plants? How much energy to boil water to make the dyes, and run her sewing machine, light her workshop? Burgess estimates that fibershed clothes are less environmentally costly, but the data is not in yet. For Living on Earth, I’m Lonny Shavelson.

GELLERMAN: To see a slideshow of the Fibershed Project, go to our website L-O-E dot org.

Links

Living on Earth wants to hear from you!

Living on Earth

62 Calef Highway, Suite 212

Lee, NH 03861

Telephone: 617-287-4121

E-mail: comments@loe.org

Newsletter [Click here]

Donate to Living on Earth!

Living on Earth is an independent media program and relies entirely on contributions from listeners and institutions supporting public service. Please donate now to preserve an independent environmental voice.

NewsletterLiving on Earth offers a weekly delivery of the show's rundown to your mailbox. Sign up for our newsletter today!

Sailors For The Sea: Be the change you want to sea.

Sailors For The Sea: Be the change you want to sea.

The Grantham Foundation for the Protection of the Environment: Committed to protecting and improving the health of the global environment.

The Grantham Foundation for the Protection of the Environment: Committed to protecting and improving the health of the global environment.

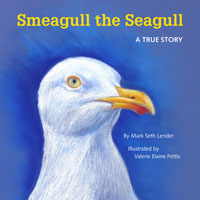

Contribute to Living on Earth and receive, as our gift to you, an archival print of one of Mark Seth Lender's extraordinary wildlife photographs. Follow the link to see Mark's current collection of photographs.

Contribute to Living on Earth and receive, as our gift to you, an archival print of one of Mark Seth Lender's extraordinary wildlife photographs. Follow the link to see Mark's current collection of photographs.

Buy a signed copy of Mark Seth Lender's book Smeagull the Seagull & support Living on Earth

Buy a signed copy of Mark Seth Lender's book Smeagull the Seagull & support Living on Earth